Technology is an increasingly important part of the science of forest management. The forestry technology, machinery and equipment we choose to use, ensures greater safety, efficiency and sustainable results for landowners, forests and those that work in them. The evolution of technology over the past 200 years has greatly influenced the success of Australia’s forestry industry, into the $3.6billion renewable resource industry it is today. In this blog we take a look at the changing landscape of forestry machinery and timber harvesting equipment through the years.

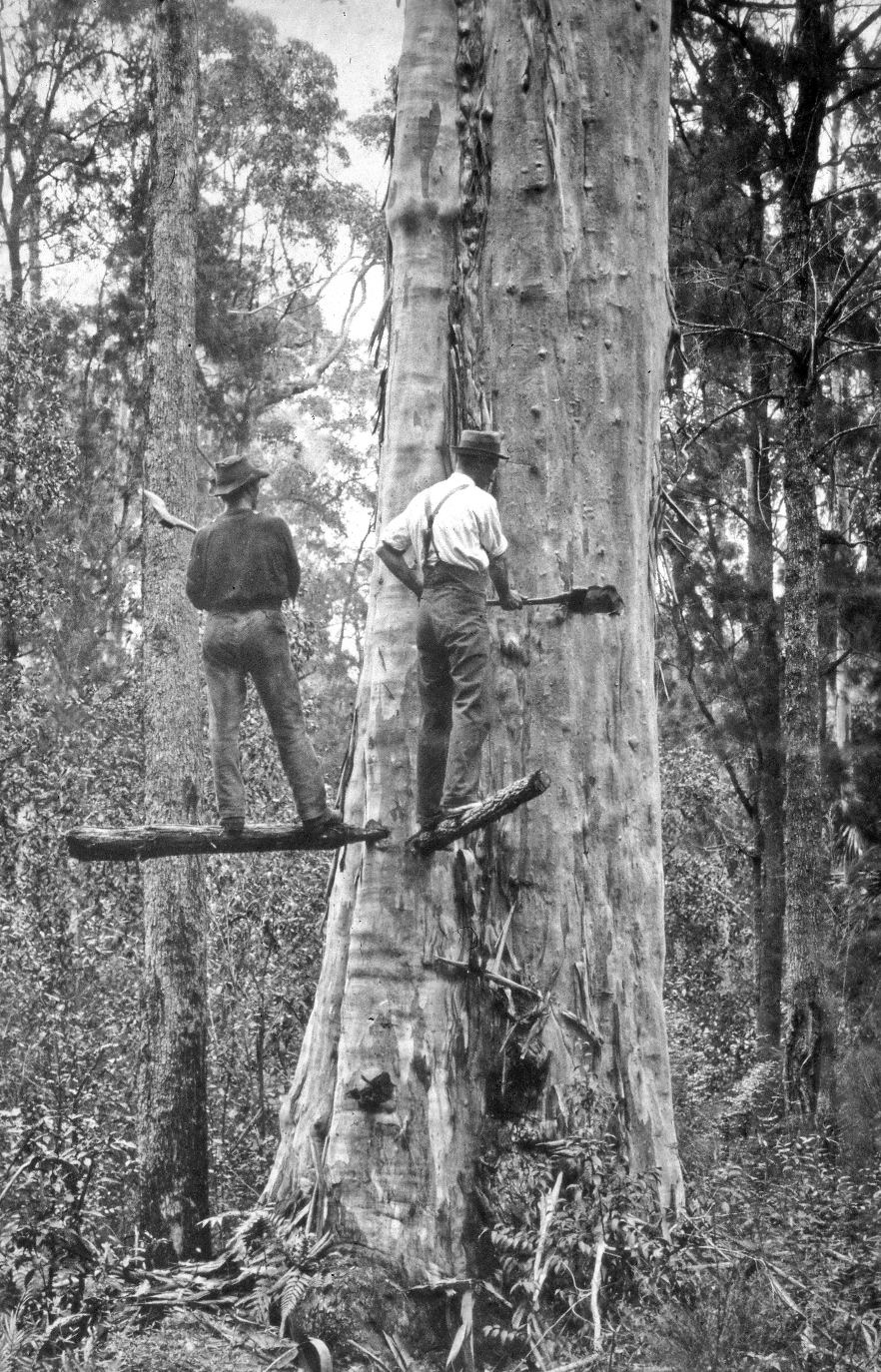

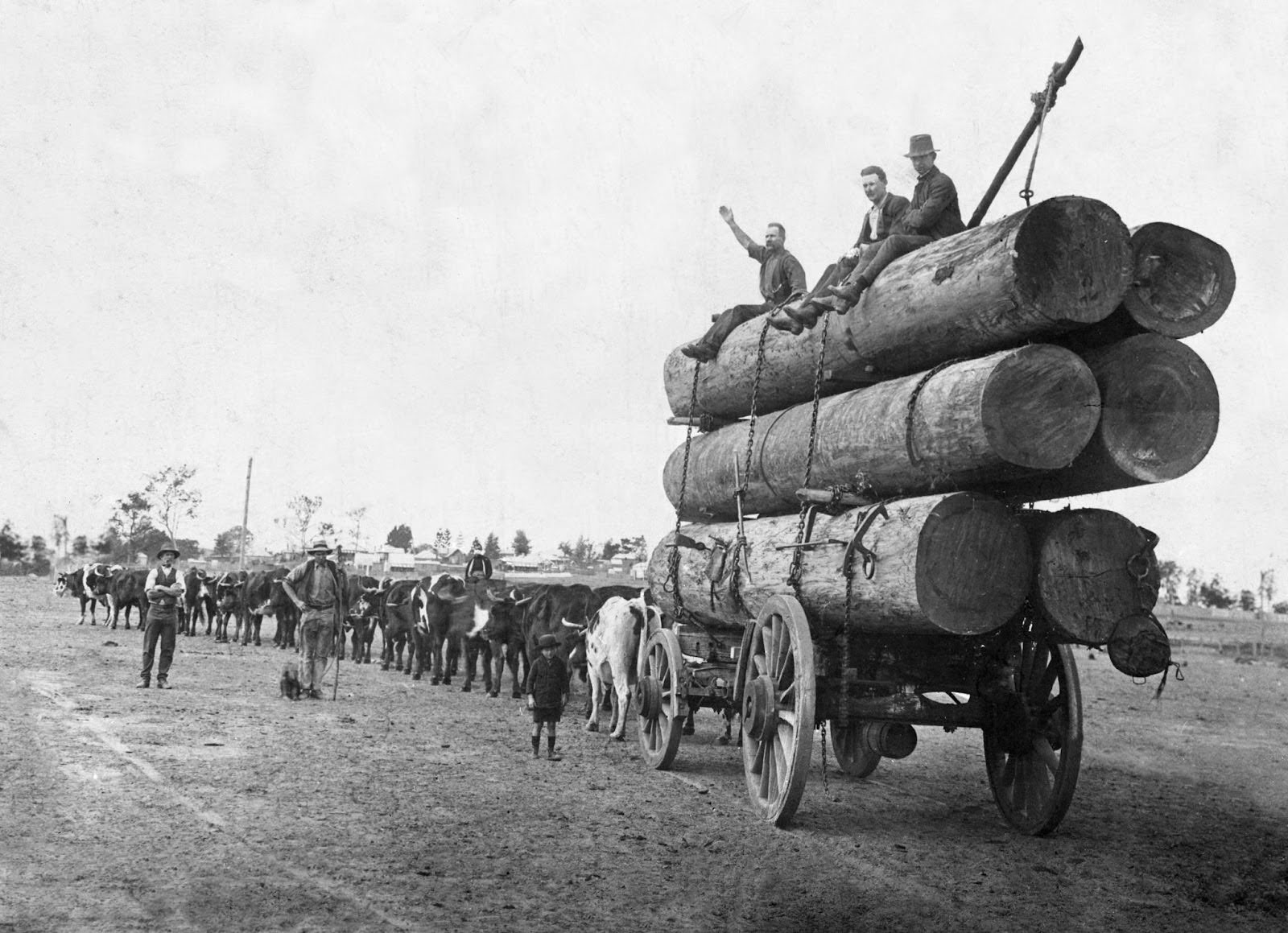

The First Forestry Technology: Bullocks and Hand Tools

The 1800’s saw the introduction of foresters, with the first government issued timber licences granted in 1820. It wasn’t until almost 100 years later however that the first forestry legislation was passed in 1916 (Forestry Corporation). These initial foresters relied on simple but sharp tools such as axes and hand saws, alongside bullock teams and drivers to haul timber to the dock for further transportation by water. Sustainable Forest Management Director Siman’s family have a long history in forestry, with Siman’s grandfather owning one of the first successful bullock teams in the NSW Clarence Valley at Glenreagh.

Chainsaws

The next innovation to follow was the electric and gasoline powered chainsaw, developed by Andreas Stihl in the late 1920’s. Now this global brand is known as Stihl. This innovation enabled trees to be cut much faster and with more precision. It also enabled a reduction in the manpower required to fell a tree (Department of Agriculture, Fisheries and Forestry).

Today’s Forestry Technology: Forestry Heavy Machinery

Next came the advent of large forestry machines built to extract, load and transport harvested logs. This includes forestry vehicles such as dozers, skidders, excavators and mechanical harvesters.

Dozers

Used for constructing roads, log dumps and snigging logs (hauling logs along the ground from tree stump to log dump). Built with tracks instead of wheels, dozers have a blade on front which can be used for moving vegetation and loading logs to trucks, and a winch on the back for snigging. Dozers can also be used to remove bark, using their blade. As such they are still a common machine used in modern forestry.

Skidders

Later introduced as a more efficient and economical alternative to dozers for snigging on flat land. For steep inclines dozers are still predominantly used from an access and safety perspective.

Excavators

An option for road and log dump construction, as well as loading logs onto trucks for haulage. There are excavators designed specifically for forestry purposes with log grabs, which make them the machine of choice to operate at the log dump.

Mechanical Harvesters

Most recently, the mechanical harvester was incorporated into modern forestry management for its innovation in safety and efficiency. This machine replaces the requirement for manual falling (or the vast majority) as a tree logging machine. Whereby a manual faller typically fells trees for profitable timber production, the mechanical harvester is predominantly used for silvicultural purposes. Mechanical harvesters accelerate harvest operations and maximise the utilisation of the tree. They can cut the tree off higher up than a manual faller can (due to safety limitations), therefore meaning they are able to utilise more of the tree for saleable wood products, minimising wastage and harvest residue/fuel load left behind.

The advancement in the tools and equipment we use today enables us to carry on the traditions of forestry, whilst using industry leading sustainability practices for the long term benefit of the forest and landowners now and for future generations to come.

If you would like to better understand the potential of your private native forest or plantation, we encourage you to get in touch with us today for a free no-obligation assessment. Please Contact Us or call 1300 367 378 today.