Have you ever wondered what happens to the timber harvested from New South Wales forests? Or how far the logs travel to be processed and what they are turned into? In this blog we follow the journey of our logs from private native forestry operations to the sawmill and beyond.

What happens at the sawmill

Almost all native timbers harvested in NSW are from hardwood eucalypt forests along the coast and tablelands (Timber NSW). This timber once harvested is hauled to a saw mill for primary timber processing in one of six different ways.

The six methods of primary timber processing:

- Retained in round form: to be sold as high value, structural products such as electricity transmission poles, piles and bridge girders.

- Sawn: the most popular method, with sawlogs providing the greatest value for both the forest owner and the primary processor. The sawlog quality greatly determines the end use and therefore the most suited manufacturing process.

- Peeled or sliced: producing high value veneer with multiple future uses.

- Split: lower quality logs are often split or cut into fence posts or firewood.

- Chipped: low quality trees not suited to milling are turned into woodchip.

- Crushed: saved for the lowest quality wood, which is turned into sawdust to be used by the equine, chicken or landscaping industries.

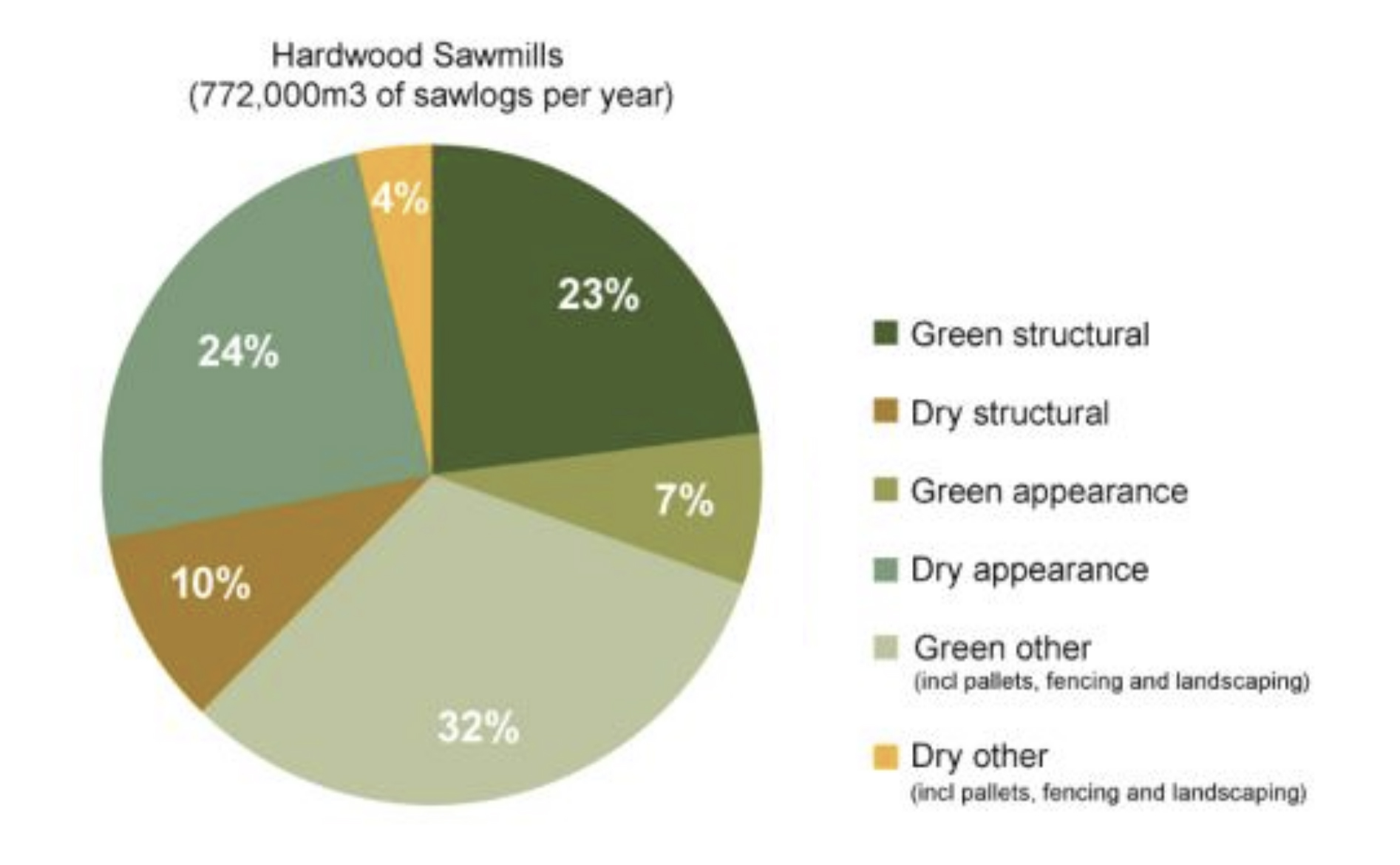

The processed timber can either be sold as green, or dry with both air-dried and kiln-dried options, further increasing its value. Dry timber is considered stronger and more durable than green untreated timber. The below illustrates the mix of sawlog types produced by NSW hardwood sawmills.

Did you know that in New South Wales alone, there are 63 hardwood sawmills? Together, these mills collectively yield an impressive annual throughput of over 750,000 cubic metres of sawlogs, as reported by Timber NSW.

We work with over two dozen sawmills, multiple pole yards and firewood customers. Some examples of these include Hayden Timbers in Gum Scrub, specialising in producing high quality green sawn wood products. Hurford in Tuncester, a third-generation family owned processor that offer kiln dried seasoned timber products such as flooring and decking, and Koppers Wood Products, Australia’s largest supplier of electricity transmission poles. Once the timber has been primary processed, some is selected for secondary processing to add further value which is conducted through a broad range of manufacturing processes. These processors range from large-scale, capital intensive manufacturing operations employing many people through to small scale operations focussing on individual craftsmanship.

Secondary timber processing

Sawn timber is often further processed into popular construction products including mouldings & joinery and frames & trusses. With sliced veneered timber being further processed to produce plywood and engineered flooring and doors. Secondary processing of chipped timber is used to create commodity products such as paper, cardboard, mdf and engineered products. Whereas secondary processing of the high-value round timber focuses on treating the wood with preservatives to increase durability.

75% of Australia’s sawn timber is used in residential construction

The timber and forest products industry in New South Wales is an important component of other industry sectors in Australia. In particular, the timber industry underpins vitally important supply to the Australian design, manufacturing, construction and property sectors. Three quarters of NSW sawn timber is used in home construction across Australia, of which 5% is used by the kitchen sector alone, with a further 20% used by the furniture industry (Timber NSW).

What happens to any leftover timber from processing

Forest and Wood Products Australia estimate that by 2050, 5.6 million tonnes of sawmill residue could be produced as a by-product of processing 11.3 million cubic metres of sawlogs. Around 90% of these residues are expected to be used in some form. 11% are estimated to be used to be burnt to generate power on site, reducing the reliance on grid supplied electricity, 35% will be used for wood chips, 11% for processing into wood panels, 14% into wood pellets and 8% into briquettes.

You can read more about biomass in our dedicated renewable bioenergy blog.

Keen to ensure your own private native forest is managed sustainably?

Connect with us today. As leaders in sustainable management of private native forest along the NSW North Coast, Sustainable Forest Management helps dozens of private landowners each year to successfully manage their forests for the best long-term outcome. Get in contact or call us on 1300 367 378 to arrange a free assessment and valuation of your forest.